VNIIA has unique computerized and multi-purpose process-engineering and testing equipment, tools and gears, measuring equipment and analytical devices, computing capabilities and qualified staff to create such products. All types of activities become more and more automated; end-to-end working cycles are implemented from the beginning of design to the fabrication of a product and its testing.

The 3-D and 4-D mathematical modeling and prototyping is widely used for complex components using 3-D printers, enabling to fabricate a component or a prototype within several hours by “growing” it of a special polymer leaving out the stages of design and fabrication of complicated gears and mechanical machining on a metal-cutter. This technology is capable of producing unique and complicated solid 3-D components with closed interior cavities of variable structure that cannot be fabricated mechanically.

The Institute’s production shops are equipped with high-performance NC-machining technique, automatic machines, semiautomatic machines and standard machines that allow components of any complexity to be manufactured starting from blanking operations to final precision machining. Depending on the type and hardness of the material, strength of a component and the required preciseness of machining, the components are fabricated using cutting, pressing, laser machining, eclectic erosion, and etc.

To provide the required mechanical properties, the critical parts made of metals and alloys are subjected to thermal treatment in furnaces with automatic temperature mode during the process. The most loaded parts and those with complicated geometry are subjected to thermal stabilization using both heating and cooling in special chambers.

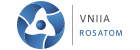

To protect the products during the whole lifetime in severe environment and to put the marking on the products, the Institute’s production shops are equipped with the machines for galvanic, chemical, lacquer and composite coating of anti-corrosion and decorative purpose.

VNIIA’s products incorporate the techniques of the permanent connection using soldering and welding of various types (argon-arc, laser, electron-beam, and diffusion).

There is equipment available for binding dissimilar materials to produce glass-metal and metal-ceramic units.

The majority of electric insulating parts are fabricated of the thermoplastic and thermosetting plastic materials at automatic presses that cover the needs of both pilot and serial manufacture at VNIIA. The casting and machining of ceramics is performed.

The Institute has unique equipment for fabricating high-voltage and high-current components using combined winding of polymer films, foils, magnetic tape, and wires. There is a wide application of filling and impregnation with liquid and polymerizing dielectrics, plastic foam and compounds with various functional filling agents.

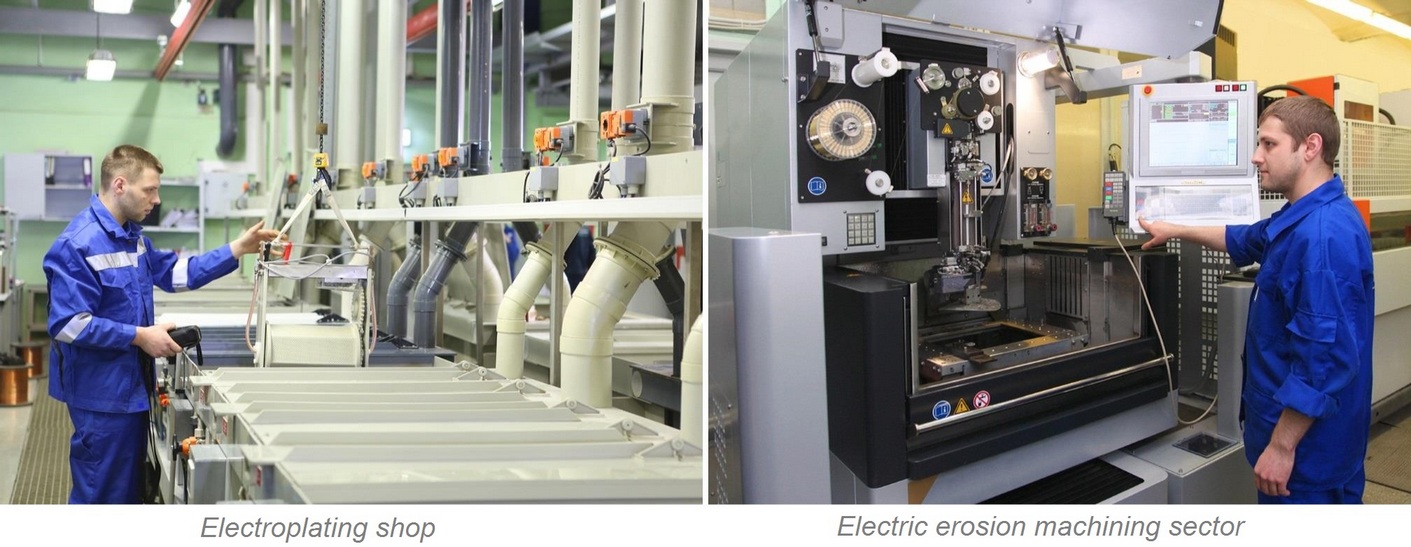

The semiconductor production shops are equipped with vacuum plants for deposition of thin (nanoscale) and thick films of mono- and poly-element materials, and for diffusion, epitaxy, and etc.

The prototype models and the serial products are subjected to various tests. All these tests are carried out using the Institute's experimental and testing equipment, which includes dozens of systems and facilities that allow studying physical phenomena, behavior of materials and products in extreme environment, measuring an enormous range of physical parameters and characteristics. These systems include both unique setups, available to very few leading research centers in the world, and those specifically designed by VNIIA experts and having no analogues.

The electronics is manufactured at the advanced automatic lines suitable for production of electronic systems of any complexity. There are reliable automatic lines for assembly of complex electronic equipment using surface mounting and wire wrapping techniques.

Automatic quality control of components soldering on printed boards is provided, as well as the in-circuit testing of assembled units and the control of complex electronic systems wiring.

Generally, the production complex is capable of producing prototypes and experimental models of all types of products, which is required for research and design efforts, and provides series manufacture of the products developed by the Institute.